LYNCH STANDARD VALVE PACKAGES

STANDARD SPECIFICATIONS

Standard Material:

Ductile Iron

Max Pressure:

Up to 5000 PSI.

Coil Ranges:

12 VDC, 14 VDC, 24 VDC, 28 VDC & 115 VAC.

Connector Type:

ISO/DIN 43650 Form A Connector & Deutsch DT04-2P Connector.

APPLICATIONS

Mobile Cranes

Lynch Load Lock Blocks help securely hold suspended loads even during engine shutdown or hydraulic failure. They lock the actuator in position, preventing boom or jib drift, especially crucial when lifting heavy materials at height. This minimizes risk of unintended movement, protecting personnel and equipment.

Scissor Lifts

Lynch Load Lock Blocks protect against platform descent due to pressure loss or hose failure. This ensures worker safety at elevated positions by locking the hydraulic actuator, even during system power loss or emergency stops.

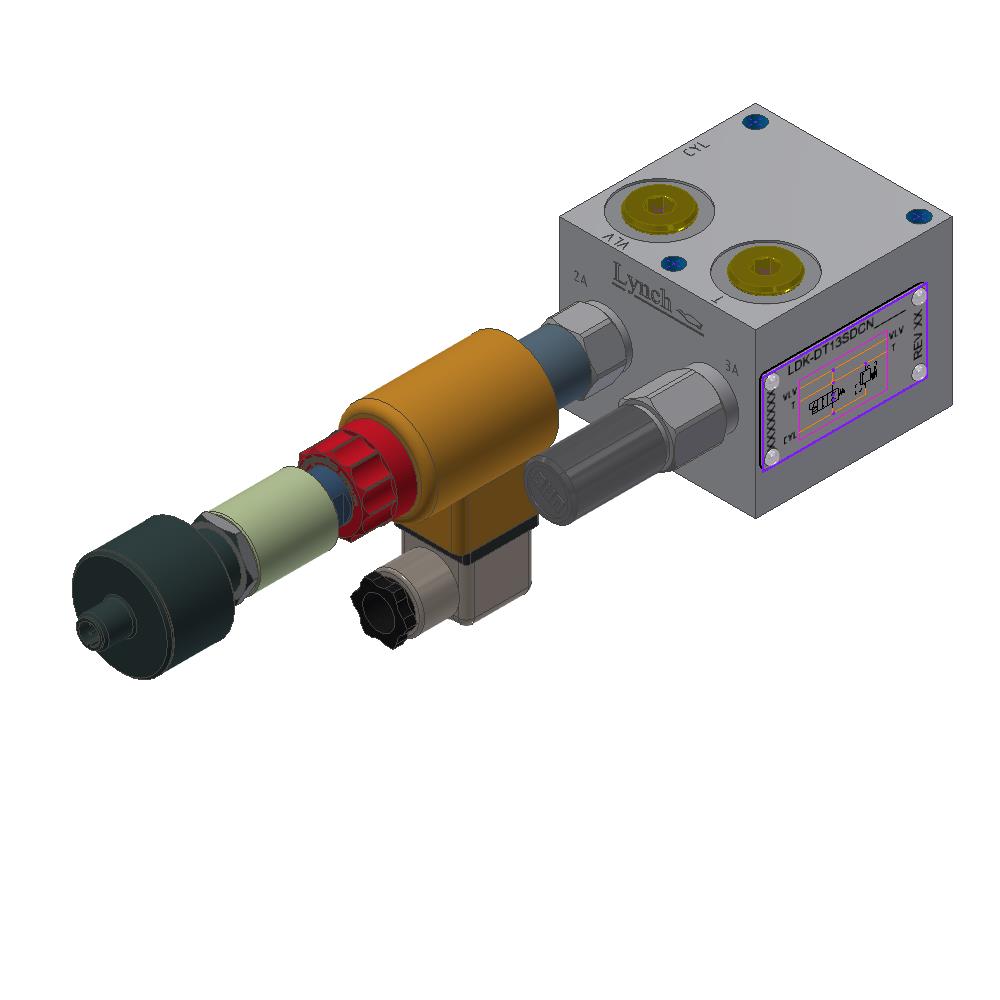

LOAD LOCK BLOCK

Lynch Load Lock Blocks are critical components in hydraulic circuits designed to support suspended or potentially dynamic loads. If applied properly, these valves prevent actuator movement when electrical power is lost, thereby enhancing system integrity. In industrial and mobile hydraulic applications, these valves serve to counteract potential hazards arising from pressure decay or hose rupture. By hydraulically isolating the actuator chambers, these valves lock the load in place, mitigating the risk of uncommanded descent or drift. [Qualified personnel [PSR engineer] must review the integration of this module within the present setup to ensure functionality of the existing circuit is maintained.]

FEATURES AND BENEFITS

- Multiple sizes for different flow requirements.

- Relief settings according to requirements.

- Logic Elements with Position Switch.

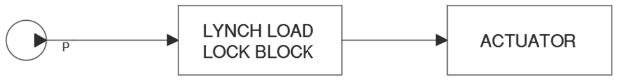

BLOCK DIAGRAM

- SITE MAP

- PRODUCTS

- PARTNERS

NEWSLETTER