LYNCH STANDARD VALVE PACKAGES

STANDARD SPECIFICATIONS

Max Pressure:

5000 psi continuous

Inlet Options:

Single & dual pump inlets

Input Options:

65, 130 or 260 GPM

Max Flow:

170 GPM

APPLICATIONS

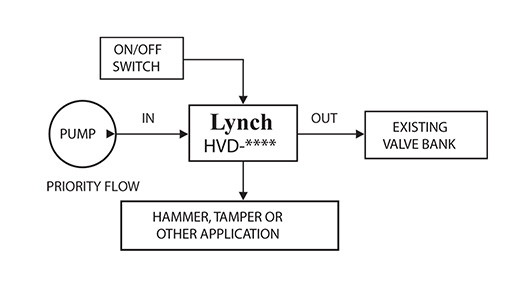

Hydraulic Hammers - Attachments are added to excavators and other machines to allow for more flexibility. The fastest and least complicated way to do this is by using a Lynch Hammer Valve between the pump and the main control bank of valves. This makes it possible to use the existing pump to run the attachment and still have full machine movement.

Hydraulic Fans or Water Pumps - The machine flow goes to the connected component controlled flow port first and then any excess flow goes back to the tank or other actuators. The main advantage is that it can be turned on and off, and flow and pressure are controlled independently of the excess flow port or system pressure.

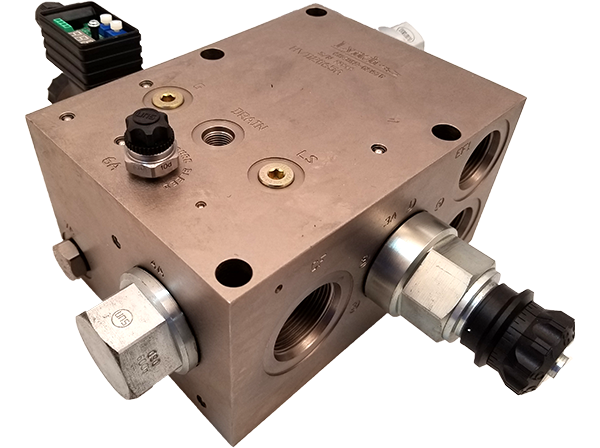

PRIORITY FLOW HAMMER VALVES

Primarily used in the mobile industry, hammer valves are solenoid operated priority flow control valves with pressure adjustability in order to prioritize and/or add additional functions to heavy equipment. Priority hammer valves provide reliable priority flow for breakers, grapples, tampers, grinders, mowers, saws, and much more! Packages in this family suit multi-function accessories, wrist-a-twist, sheers, de-limbers, etc. Lynch Priority Hammer Valves have valve actuation for electric solenoid (12VDC, 24VDC, 110VAC, with manual override), proportional, hydraulic pilot, and pneumatic pilot.

Lynch's NEW proportional 1065 Hammer Valve integrates Sun Hydraulics' XMD directly into the design. Flow can now be set via Bluetooth making it simpler to program. This compact design decrease cost and is more energy efficient because there is no need for a check valve on the CF port.

FEATURES AND BENEFITS

- Robust hydraulic subsystem.

- Selectable priority flow control.

- Allows user to run with a lower secondary pressure on the control flow.

- Ideal for applications where optional attachments are required and no auxiliary spool is available.

BLOCK DIAGRAM

BUILD A HAMMER VALVE

- SITE MAP

- PRODUCTS

- PARTNERS

NEWSLETTER