- All Blogs

- Community

- Events

- News

What are hydraulic manifolds?

A hydraulic manifold is a component that regulates fluid flow…

Lynch Fluid Controls Embarks on a Cutting-Edge ...

In a significant stride towards innovation and efficiency, Lynch Fluid…

The Importance of Fluid Power in Aerospace And ...

Fluid power is a technological solution widely integrated into several…

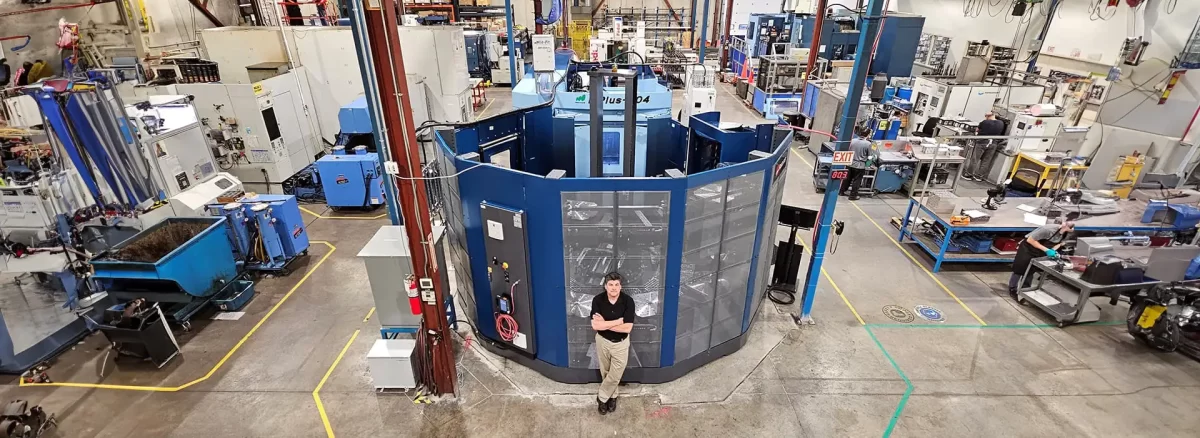

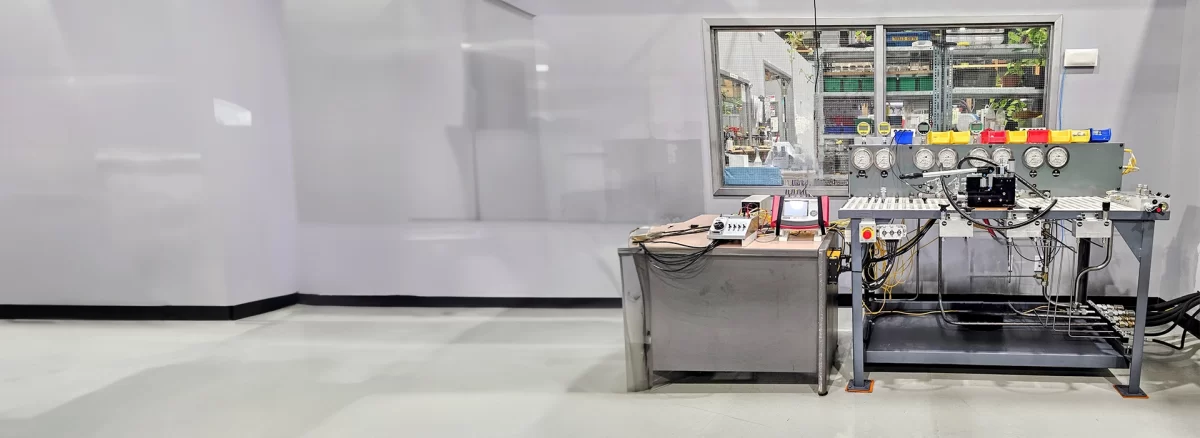

Lynch Fluid Controls Opens New Research and Dev...

We are thrilled to announce the opening of Lynch Fluid…

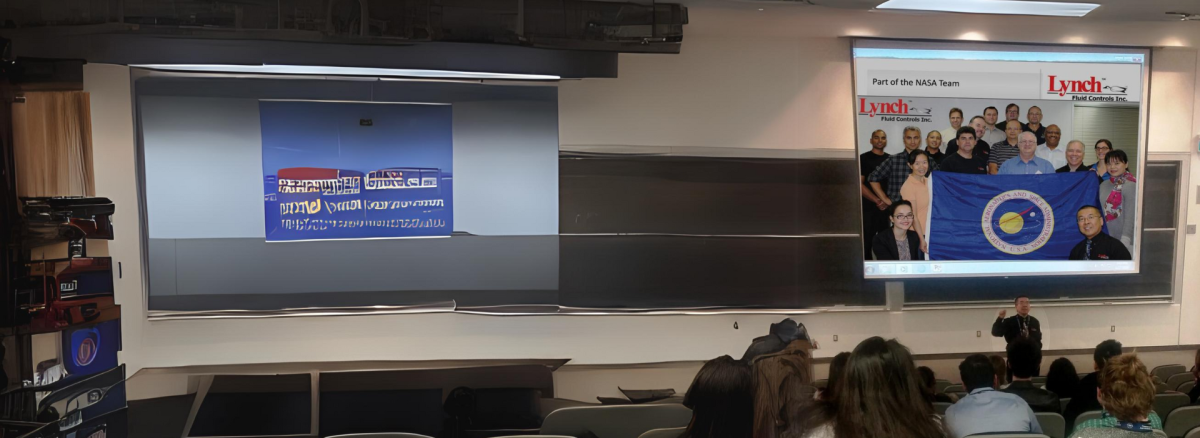

Space for Business: NASA chooses Lynch Fluid Co...

In the space market, collaboration with innovative and reliable partners…

Lynch Now Offering HPUA & T Control Option...

We are excited to announce the launch of Sun Hydraulics…

ARTEMIS I and the future of Space Travel

Artemis I was a significant mission for NASA, as it marked…

Ecoline – New Energy efficient Valves fro...

BE A PART OF THE SOLUTION ‘Reshaping the cartridge valve…

Hydraulics in Defense and Aerospace

When thinking about hydraulic applications, defense and aerospace are quite…

Enovation Controls and Lynch’s Partnership

Enovation Controls has been a proud supplier of rugged displays, controls…

Driving for Safety – Lynch’s Integrated Cus...

The Fluid Power Journal is featuring Lynch Fluid Controls in its December…

Enovation Controls’ New Murphy PowerView Disp...

Enovation Controls announces the release of their Murphy PowerView® 700, a 7-inch…

Lynch highlighted in Drop The Pressure Magazine

Read all about Lynch’s journey through the years from our…

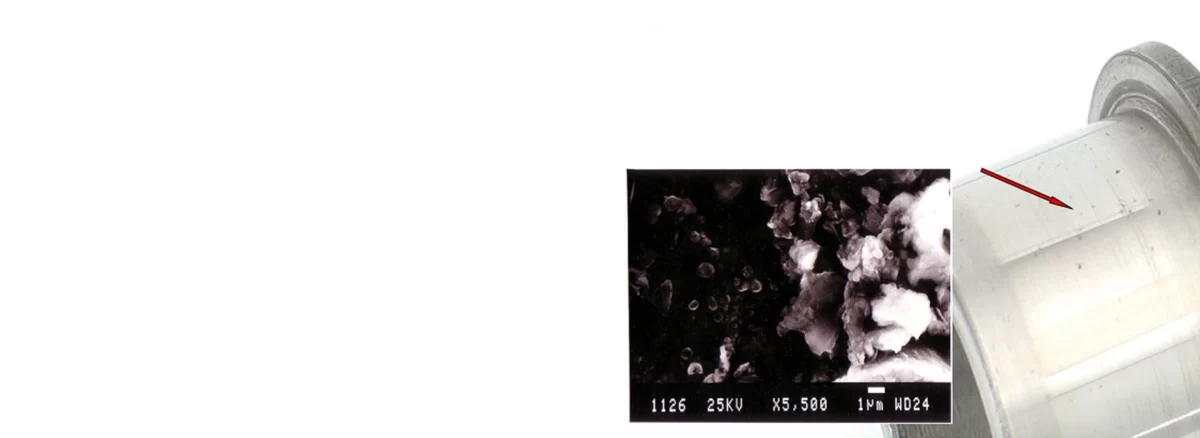

Magnom – Future Proofing of Hydraulic and Lub...

We must ‘Future Proof’ our design specifications and continue to…

Sun Hydraulics – Motion Control for Mobil...

Sun delivers smart solutions for demanding applications in all your…

Lynch’s Green Roof In Full Bloom This Summer

“As a family owned business, I feel it is our…

Lynch Fluid Controls In Attendance at Plastec E...

We are excited to be attending Plastec East for the…

Success at The Big Event Canadian Mining Expo 2018

It was great to see long standing customers & “dig…

Forging a U.S. Presence – How to Access the U.S.

BUFFALO, N.Y.—Lynch Fluid Controls Inc., established in 1987, is a…

Sun to buy quick-release hydraulic couplings ma...

Sun Hydraulics announced that it has entered into a definitive…

FLeX Series Solenoid Valves and Coils

Designed to outperform comparable valves in the market, FLeX Series…

Toronto Students Advancing Aerospace 4th Annual...

Along with Pratt & Whitney, Safran Landing Systems, The Sky…

Exporter Insights 2018 – Ernie Lynch Feat...

Exporter Insights 2018 is a national report by CanadianManufacturing.com focused…

Lynch Fluid Controls U.S. expansion takes off w...

Invest Buffalo Niagara worked with Lynch to set up cross…

Sun FLeX™ Series Solenoid Valves & Coils...

Sun Hydraulics has launched its new Sun FLeX™ family of…

Choosing the right counterbalance valve –...

This webinar recording explains Sun’s relief valve families and how…

The Canadian Manufacturing and Technology Show ...

The Canadian Manufacturing and Technology Show (CMTS) is Canada’s largest…

Take Our Class to Work – The Learning Par...

Lynch is proud to support #TheLearningPartnership: a nationally recognized organization. It…

Lynch Fluid Controls Electronics Showcase ̵...

Lynch Fluid Controls attended the 2016 Fluid Power Conference held…

Lynch Sponsors IIBA Toastmasters

Surveys about our fears commonly show fear of public speaking…

New QuickDesign™ with SmartConnect

Define your specs as you build your schematic. Submit to…

Lynch Company Overview – MinExpo 2016

Representatives of Lynch Fluid Controls describe the company’s 30 years…

Lynch Fluid Controls Overview

In today’s dynamic global markets, you need partners who can…

Take Our Kids to Work Day: November 2nd 2016 at...

Lynch is committed to helping educate youth about the world…

The top 7 reasons that hydraulics will be aroun...

In some ways, hydraulics is an ignored technology. The research…

Canada Export Achievement Award Finalist: Lynch...

Lynch Fluid Controls was named a finalist for the Clean…

Ernst & Young 2013 Entrepreneur of the Yea...

We are proud to announce that our president Ernie Lynch…

Intl. Minister of Trade Ed Fast Visits Lynch: H...

The Canadian Minister of International Trade, the Honourable Edward Fast,…

The Ernst & Young Entrepreneur Of The Year...

The Ernst & Young Entrepreneur Of The Year award is…

Best in Business: Celebrating 25 Years!

Lynch Featured in Mississauga Business Times As written by the…

Fluid Power Conference & Expo 2010

President Ernie Lynch, along with his Marketing Team, discuss why…

Hydraulic Hammer Valve Spotlight

A product spotlight of Lynch’s Standard Valve Package Priority Control…