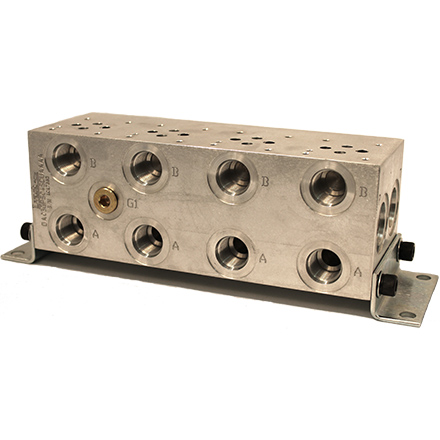

LYNCH BAR MANIFOLDS & ACCESSORIES

STANDARD SPECIFICATIONS

Standard Materials:

Aluminum-6061T6 and Ductile-654512

Other Material Options:

Mild Steel or Stainless Steel

Maximum Pressure:

Alu 3,000 PSI, Duc 5,000 PSI

Special Finishes:

Black Oxide, Electroless Nickel Plating, Anodizing

Mounting:

4 Bolt mount design; for vertical mounting or with foot bracket

APPLICATIONS

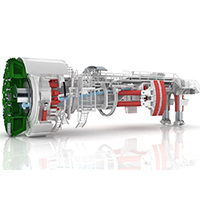

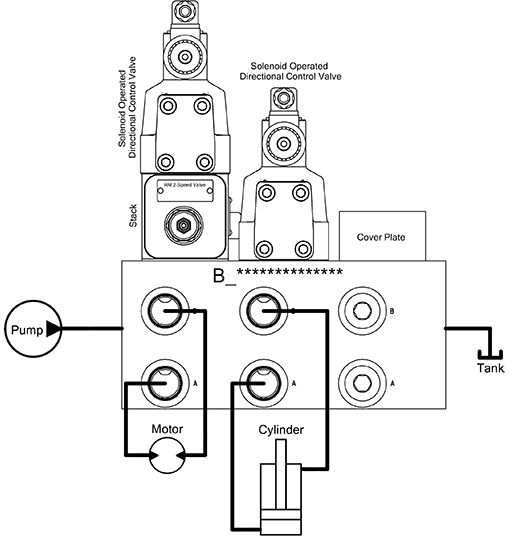

Tunnel Boring Machines - Different sizes of Lynch Bar Manifolds are used to control the Drill Carriage, Erector Slide, Clamps, and many more hydraulic devices inside these big and remarkable machines. Each station controls the direction of one movement, its speed and its force with different modular valves depending on the different requirements.

Test Stands - Lynch Bar Manifolds are being used to test Airplane Landing Gears. One station controls the hydraulic actuator pushing the landing gear towards the front while a second one pushes to the side. Both cylinders use the same pump but they need different speeds and pressures, so each station has different controls mounted in sandwich bodies under the directional valves.

Lynch bar manifolds have a similar look to what the industry is accustomed, but are enhanced to maximize performance while accommodating the highest number of standard options in a more uniform and easier-to-install package. We looked beyond established layouts and developed a series of stringent design parameters to configure our products. Bar Manifolds reduce plumbing, number of leak points, and improve the appearance and maintenance of the hydraulic system by centralizing the location of the valves. Directional control valves change the direction of fluid flow. These patterns usually have oil passage holes with options for X & Y ports. Threaded or flanged ports provide the user connections with manifolds.

FEATURES AND BENEFITS

- Bar manifolds are designed to have the highest flow rate and lowest pressure drop in the industry.

- Internal galleries are equal to or greater than the nominal port connection in order to minimize pressure drops and fluid velocities.

- Port spacing and edge distance has been maximized to ensure easier installation and servicing.

- Common drain ports, are supplied on both ends of the manifold for ease of installation and connecting a series of manifolds without the need of tees and elbows.

- P to T Relief cavities in Sun and Common Cavity form are standard options, while the ISO and other types are non-standard options.

- No variation in the design layout for each Model regardless of Port Code.

- Manifolds with Flange Ports are available with UNC mounting threads and SAE Ports or with Metric mounting threads and Metric Ports as standard.

- "P" and "T" port isolations are available for manifolds up to 10 stations. A second gauge port is provided with "P" port isolations when possible.

- UNC or Metric mounting bracket kits come standard with all bar manifolds.

- Stud rods are available ranging in sizes from ISO 03 to ISO 08 simplify installation & save you money.

- Distributors Dream – Stocking our product is a breeze.

BLOCK DIAGRAM

BUILD A BAR MANIFOLD

- SITE MAP

- PRODUCTS

- PARTNERS

NEWSLETTER