INNOVATIVE HYDRAULIC SOLUTIONS

Hydac operates worldwide, offering an extensive product range to cover all areas of fluid technology. The products range from components and sub-systems, through to complex controlled and regulated drive units for mobile and industrial machines and systems. Hydac components can be found in all areas of industrial and mobile hydraulics. Hydac solutions cool and lubricate gears in wind turbines, work in the tensioning hydraulics of modern machine tools, cushion the cabs on agricultural machinery, support the working hydraulics of excavators, and inspect and test the loading capacity of wings on the Airbus A 380. Hydac units adjust the parabolic troughs of solar energy plants or actuate valves and armatures in power plants. Vibrations in large-size diesel engines are damped by hydraulic accumulators, and the shaft movements on drilling ships are compensated for with hydraulic cylinders.

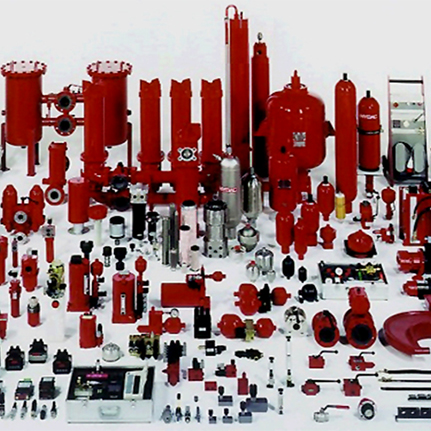

PRODUCT OFFERINGS

Hydac offers a comprehensive range of products in hydraulics, electronic control technology, solenoid technology and control sensors as well as fluid sensors/condition monitoring and fluid control products. Don’t see what you’re looking for? Contact Lynch to find what you need.

HYDRAULIC ACCUMULATORS

Wherever hydraulic tasks need to be performed, Hydac hydraulic accumulators can help. They are versatile, make your machine more convenient to use, secure your hydraulic system and are used to increase the energy efficiency of hydraulic systems and for many other tasks.

Available options include:

- Hydropneumatic accumulators

- Bladder accumulators

- Piston accumulators

- Diaphragm accumulators

- Metal bellows accumulators

FILTRATION

Perfect component protection through perfect filtration. For more than four decades, Hydac has been devoting themselves to solutions for prolonging service lifetimes and protecting components. The enhancement of availability of your hydraulic and lubrication systems and shorter down times are our main objectives. In addition to high-quality single components such as hydraulic filters, clogging indicators and ventilators, you also receive from us well-thought-out filtration systems and clever complete tank solutions.

Filter Assemblies - Including Tank breather filters, Inline filters, Return line & suction boost filters, Suction filters, Block mounting filters, Offline filters, Return line filters tank mounting , and Special filters.

Clogging Indicators - Used for monitoring the filter. If the contamination of the filter element increases, then the loss of pressure in the filter housing will rise. As soon as a particular limit value is reached, the clogging indicator indicates an imminent element replacement.

Features include:

- Indicator of dynamic or differential pressure

- Optical, electrical or electronic signal

- Wide different of response pressures

Filter Elements - The operating fluid passes through the filter element and is thereby reliably relieved of solid particles and other fluids. Depending on the requirements and the hydraulic filter construction, various filter materials (surface/depth filters, coarse/fine filters), filtration ratings (1 to 200 µm) and designs (return line/suction/pressure filter elements) are used.

Spare Parts and Accessories - Include other adaptors, connector plugs, silicagel filling, repair kits / seal kits, dirt retainers, logging indicator adaptors, heads, bowls, cover plates, and other spare parts and accessories.

VALVES

Valves monitor the pressure, flow rate or flow direction of hydraulic fluids. Thanks to a variant-rich programme, Hydac valves offer almost all of the possibilities for structuring hydraulic systems – whether stationary or mobile. In this area, Hydac offers cartridge, slip-in, plate mounted, subplates and inline connection valves up to nominal size 63. The performance ranges up to: Qmax = 6000 l/min Pmax = 630 bar.

Pressure Valves - The Hydac pressure valve programme encompasses practically all pressure control functions which are used in hydraulics. Pressure valves influence the system pressure in a system by means of mechanical or hydraulic modification of cross-sections. Hydac offers both direct acting and pilot-operated pressure valves in this area.

Check Valves - Shut-off valves from Hydac are poppet and spool valves for the controlled opening or closing of lines and other hydraulic components. They control inlet, discharge or outlet of hydraulic fluids.

Directional Valves - Hydraulically operated directional spool valves ensure a secure connection between paths at the time of their actuation. Electromagnetically actuated directional valves influence the path of a flowing medium, i.e. block, permit, divide, combine it. Hydac offers in this range direct acting and pilot-operated two-way poppet valves (WS and WSM) and direct acting spool valves (WK and WKM).

Flow Valves - Flow valves influence the flow rate in a system by means of mechanical or hydraulic modification of throttle cross-sections. Hydac offers both manually and hydraulically controlled valves in this area.

Proportional Valves - Hydac proportional valves are electronically actuated valves for which the output value - pressure or flow - is changed at the same ratio as the inlet value. Control electronics and proportionally designed solenoids are required for actuation. Just as it is true in the hydrovalve sector, Hydac offers pressure relief, pressure reducing, needle, flow control, and directional valves.

COOLING SYSTEMS

Typical applications for Hydac cooling units are machine tools, machining centers, plastic injection machines, presses, and electrical components.

Plate Heat Exchangers - Oil-water coolers have the advantage that they can keep the oil temperature down to a very low and stable level - depending on the temperature of the water. Hydac plate heat exchangers are available as brazed and gasketed versions and offer an efficient heat transfer with small dimensions and low weight.

Air Coolers - Complete oil-air coolers with axial or radial fans for industrial and mobile applications.

Pump Transfer-Cooler-Filtration Units - The UKF unit is a compact and installation-friendly unit for cooling filter circuits in the bypass flow. The service life of the oil and of the hydraulic system can be prolonged considerably by continuous cooling and filtration in the bypass flow.

Refrigerator Units - Connection-ready cooling units for closed circuits for which a recooling of the coolant to a level equal to or lower than the ambient temperature is necessary.

Fluid-air cooling systems FLKS - The FLKS is a compact, complete fluid-air cooling system, which is used primarily for cooling and lubrication circuits. The cooling system is modular in structure and is comprised of one axial or radial fan, one tank with circulating pump and one heat exchanger. Standard version with water-glycol (W) or mineral oil (M).

Fluid-water cooling systems FWKS - The FWKS is a compact, complete fluid-water cooling system for cooling and lubrication circuits. This system is primarily used as a temperature-controlled intermediate circuit. The advantage of an intermediate circuit is that the system or the parts being cooled do not come into contact with the actual coolant, i.e. water, which helps to prevent contamination or corrosion of the system. The FWKS is comprised of one plate heat exchanger, a tank with a circulating pump and additional accessories. FWKS are available in various installation sizes. Depending on the version, water-glycol (W) or mineral oil (M) can be used as operating medium.

PUMPS

Hydac offers a wide spectrum of pumps for a variety of hydraulic applications and systems. Hydac offers fixed displacement and variable displacement pumps in various designs and pressure ranges. The spectrum ranges from 0.25 cm³/rotation to 560 cm³/rotation and covers pressure ranges of up to 400 bar.

SENSORS

Pressure sensors - Electronic pressure sensors are used for recording pressures in fluid technology systems. Functionality and form of execution are determined by the respective utilization conditions. In order to fulfill these requirements, Hydac offers a comprehensive programme from miniature pressure transducers to customer-specific multiple pressure switches.

- Electronic pressure transducers record the measured pressure variable and convert it into a proportional output signal.

- Electronic pressure switches record the measured pressure variable, process it and output a switching signal in accordance with the presetting.

Flow Rate Sensors - Offers a variety of flow rate measuring transducers and flow switches for recording the flow rate in machines and plants. The flow rate measuring transducer of the EVS 3000 series works in accordance with the turbine principle (recording the rpm of an impeller wheel rotating in the media flow). Depending on the version, additional connection openings for pressure and/or temperature transmitters are available. The flow monitors of the HFS 2000 series are based on the buoyancy transmitter measurement principle. Under these circumstances, the measurement medium deflects a spring-charged buoyancy transmitter in the flow direction, depending on the flow rate. A reed contact is fitted outside of the device. This will switch when the magnet integrated in the buoyancy transmitter reaches the preset position.

Displacement Sensors - Electronic path sensors are used for recording cylinder positions in fluid technology systems. Functionality and form of execution are determined by the respective utilization conditions. In order to fulfill these requirements, Hydac offers a comprehensive program, from simple attachment sensor to customer-specific, fully integrated sensor.

Oil Condition Sensors - Oil condition sensors facilitate online monitoring of the oil condition in stationary and mobile applications.

Temperature Sensors - For recording and evaluating temperatures, Hydac offers temperature transmitters and temperature switches for installation in pressure lines or for tank mounting. Temperature measurement transducers record the temperature and convert it into a proportional output signal. Electronic temperature switches record the temperature, process it and output a switching signal in accordance with the presetting.

Level Sensors - Electronic level sensors are used for recording fill levels in fluid technology systems. In order to fulfill the wide-ranging customer requirements, Hydac offers an extensive range of capacitive and contact-free level switches. Electronic level switches record the fill level and output one or more switching signals in accordance with the presetting. As an option, the fill level can also be permanently output as an analogue signal (4 - 20 mA or 0 - 10V).

Distance Sensors - The Hydac ultrasound distance sensors are used for measuring the distance to fluids and objects. As a result of its functional principle (measurement of the sound transmission time), it operates without contact and with a very high resolution and measurement rate.

Additional Hydac sensors include:

- Contamination Sensors

- Rotation

- Accessories

ELECTRONICS

Displays - The universal display device HDA 5500 offers the opportunity for visualization and further processing of the signals of our sensors. The device is conceived for front-panel installation with standard 92x45 mm cutout.

Type series:

- HDA 5500, microprocessor-controlled display and monitoring device for switch panel installation

Analysis Instruments - Hydac analysis devices are utilized in particular where processes are to be analyzed and optimized professionally in the context of a Contamination Management (cleanliness management) from the point of view of the cleanliness of components, systems and the fluids used.

Measuring Instruments - Hydac measurement devices are a helpful companion for many measurement tasks in fluid technology. Hydac offers an extensive array of easy to use measurement systems. Whether it be solid particles or fluid contamination, for sporadic checking or as a permanent installation, under rough field conditions or in the laboratory.

Benefits to you:

- Plannable availability of plants & components

- Avoidance of sudden downtimes

- Reduction of operating costs

- Prevention of catastrophic consequential damages to plants and associated delivery bottlenecks.

- Preventive and condition-based maintenance

Modules - Hydac control modules are eminently suitable for the control of proportional magnets in applications, e.g. pressure or directional valves, pumps, etc.

Type series:

- Proportional amplifier module EHS 2042

- Signal adjustment module EHS 2092

Mobile Controller - Hydac control technology for mobile work machines. From the components to the system. In hydraulics, electronics or mechanics, providing you with the best solution is our challenge.

Benefits to you:

- Industry experience and machinery know-how

- Modified programme of electronic controls, hydraulic components and sensors

- Electronic control devices for different system concepts and structures

- Diversified product line of tools for application development

- Extensive libraries

- Solutions for standard applications and applications with enhanced functional safety (e.g. ISO 13849, IEC 61508)

- Visualization solutions for the widest range of requirements

- Consultation and support ranging all the way to close development partnership

- World-wide technical and commercial support through our global presence

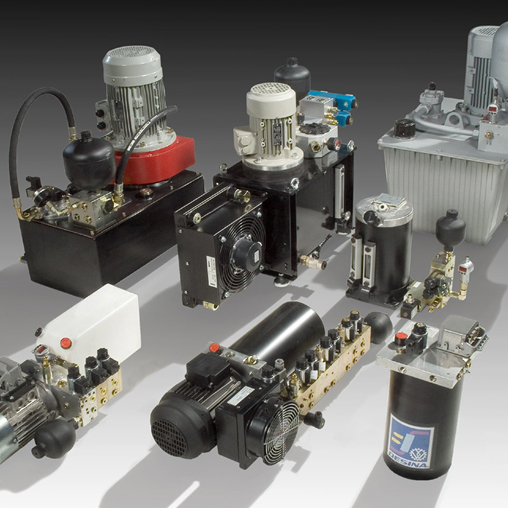

POWER UNITS

Compact power units are the most compact form of hydraulic supply, with minimum installation dimensions and high flexibility in the layout. Thanks to small flange dimensions and the optional equipment with stacking modules, the unit can be adjusted to accommodate any installation position and be expanded with new functions at any time. Depending on the available installation space, the control can be flanged-mounted directly to the power unit or integrated as a single stacking module near the consumers. In order to cover the various applications Hydac compact power units are offered in equally various forms. Compact power units are built with air-cooled motors and oil-immersed motors, water cooling is also optional available for one power unit.

| Type | Maximum pressure (bar) | Max. flow rate (l/min) | Operating mode | Description |

| DCM | 250 | 5.6 | Short-term operation S2 = starting at 1 min Intermittent duty S3 = starting at 3% | DC power units for the control of tail gates and other rigid mobile applications. Three installation positions possible – especially splash-water protected. |

| DC1 | 250 | 18.4 | Short-term operation S2 = starting at 1.5 min Intermittent duty S3 = starting at 4% | DC power units, e.g. for the control of tail gates, stockpickers, lifting platforms, lift trucks... |

| CO1 | 250 | 20 | Short-term operation S2 = 5 min* Intermittent duty S3 = 20% | Power unit with low installation height and transparent oil container (optional steel tank). For scissor-lift platforms, dock levelers, machine tools, wind energy plants, car lifters ... |

| CO2 | 250 | 20,/td> | Short-term operation S2 = 5 min Intermittent duty S3 = 25% Continuous operation** with periodic duty S6 = 25%* | AC power unit with steel container for more robust applications, e.g. energy technology, switchblades, machine tools... (** with cooler module) |

| CO3 | 70 | 18 | Continuous operation S1 | Modular construction kit for power units with energy-efficient, frequency-controlled double-pump and with servicing concept. E.g. for lathes, machine tools... |

| CA | 250 | 12.6 | Short-term operation S2 = 3 min Intermittent duty S3 = 10% | Power unit concept with oil-immersed motor. Particularly suitable for outdoor use, e.g. in travel barriers, dock levelers, switchblades... |

| HP | 500 | 5.3 | Short-term operation S2 = 3 min Intermittent duty S3 = 10% | High-pressure hydraulics in the smallest space possible. AC power unit, e.g. for clamping forming tools, brake caliper actuation... |

| L | 500 | 12 | - | Modular stacking system for high-pressure hydraulics. For the expansion of control functions of HP compact power units. |

| ML | 350 | 20 | - | Modular stacking system. Simple expandability (also retroactively) of control functions for compact power units. |

MOBILE VALVES

Sectional Directional Control Valves - Available with 1 to 10 sections and 3/8", 3/4" or 1/2" ports, with rated nominal flow from 10 up to 180 l/min and max. operating pressure of 350 bar. Available with manually, cable, pneumatic, hydraulically and electro hydraulically spool controls. Spool position indicators are an optional available in our Mobile Valves program.

Directional Control Monoblock Valves - 1 to 4 and 6 sections in 1/2" and 1". Recommended for applications with rated flows up to 160 l/min and operating pressures up to 300 bar. Spools optimized for different applications. Available with manually, cable, pneumatic, electro-pneumatic and optional electro hydraulic spool controls.

- SITE MAP

- PRODUCTS

- PARTNERS

NEWSLETTER