Fluid power is a technological solution widely integrated into several facets of the power industry. However, this solution has proven to be indispensable in aerospace and military applications globally.

Conventionally divided into hydraulics and pneumatics, fluid power systems are known for their precision, high power density, and compactness, all of which are qualities that make them integral in aerospace and military applications. Used to provide efficient energy in demanding environments and execute critical missions in equally critical sectors, the importance of fluid power cannot be overemphasized.

In this editorial, we will examine the diverse application of fluid power in military and aerospace, including the benefits, limitations, and future of this technology. We will also explore how companies like Lynch Fluid Controls offer innovative solutions to challenge these fluid power limitations in the aerospace and defence industries.

Fluid Power Technologies: Hydraulics and Pneumatics

The United States National Fluid Power Association (NFPA) describes fluid power as a workhorse of the US economy, and this is not far from the truth. Fluid power is widely integrated and utilized in several industrial sectors that keep several businesses running, thereby yielding considerable impact on the country’s economy.

Two major industries that utilize fluid power for operations are the aviation industry and the defence industry. But why exactly is fluid power important to the aerospace and military?

Fluid power can be traced back thousands of years to ancient Egypt, where it was first used to irrigate crops and boost food production. However, the concept has been improved to the point where fluid power has graduated from a simple means of creating irrigation to being applied in various industrial uses such as hydraulic pumps with electric drives and intelligence-embedded valves.

Now combined with advanced electronics systems, fluid power offers a more flexible and controlled energy system that is more efficient than electromechanical devices.

As a system utilizing fluid in energy creation, hydraulic systems pump fluid power. However, because the fluid is pressurized, it creates hydraulic energy, which is converted to mechanical energy as it is passed through valves present in the framework of the system.

Hydraulic systems typically use incompressible fluids such as oil and usually comprise components such as pumps, valves, actuators, and reservoirs. Every component works in tandem to transmit power through fluid, thereby creating a highly efficient system that can be used to operate large mechanisms.

A hydraulic system is typically made up of the following:

- A reservoir to hold hydraulic fluid.

- A hydraulic pump moves the fluid through the system and converts the mechanical energy generated during the process to hydraulic power.

- An electric motor to power the hydraulic pump.

- Valves to control the flow, and hence the pressure, of the fluid in the system.

- The hydraulic cylinder converts the generated hydraulic power back to mechanical energy, which powers the equipment.

Hydraulic systems can be found in everyday uses, such as cars, dishwashers, and gasoline pumps. However, they are also primarily used in industrial applications such as construction machines, airplanes, heavy construction vehicles, and military operations.

In aerospace and military applications, hydraulic systems are used for a wide range of operations, from operating heavy machinery on the battlefield to

controlling spacecraft movements. They play integral roles in ensuring the safety of all missions, whether on land or in the air, while also ensuring (or at least guaranteeing to a large extent) the safety of the personnel involved.

While hydraulic systems focus on using fluid to generate power, pneumatic systems are powered by compressed air or inert gases. This fluid power application uses components such as compressors, valves, and actuators to control the flow and pressure of the gas used to generate energy.

Like the hydraulic system, pneumatic systems comprise components that facilitate energy creation. Some of the major components include:

- A compressor that makes air.

- A reservoir or receiver that stores air.

- Valves to control airflow so the air or inert gas is released at the right pressure level.

- A circuit of feed lines or hose pipes that move air between the other components.

- The actuator converts the energy of compressed air or gas into a mechanical motion.

- A cylinder that generates motion from air pressure.

Together, hydraulic, and pneumatic systems make up the major parts and applications of fluid power. While they may represent the same form of power generation, they offer different advantages to industrial and technological companies, especially in defence and aerospace.

It is impossible to overestimate the significance of fluid power in the military and aerospace industries because it makes it possible to create cutting-edge defensive systems and spacecraft and ensures the security and success of crucial missions.

In the military, heavy machineries like tanks, armoured vehicles, and submarines all depend on fluid power to function. Hydraulic systems are responsible for propelling large equipment used in defence, while pneumatic systems guide and handle armament systems and missiles.

The control and power that fluid systems offer military operations are unmatched. Hydraulic systems are used to control the movement of a tank’s turret, allowing it to aim and fire with incredible precision. On the other hand, pneumatic systems are used to power the brakes and landing gear of aircraft, ensuring safe take-off and landing.

Similarly, aerospace draws power from hydraulic and pneumatic systems to function. Aircraft use fluid power to achieve smooth and precise control of flight surfaces and landing gear. Specifically, pneumatic systems power auxiliary systems like air conditioning and pressurization, while hydraulic systems are employed for braking and steering.

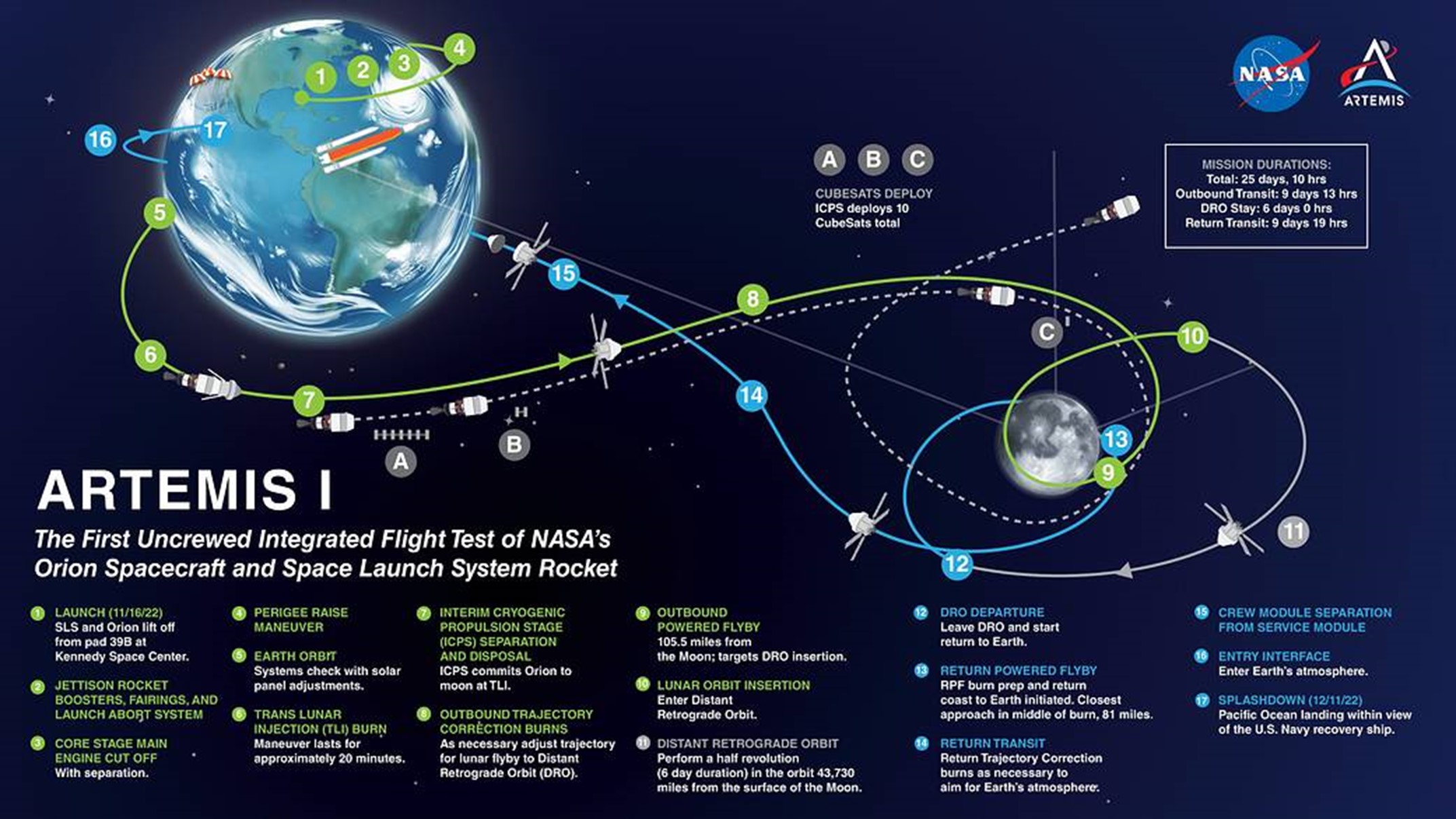

More importantly, the aerospace industry depends heavily on using fluid power to develop advanced spacecraft, satellites, and even launch vehicles like rockets. Rockets specifically utilize hydraulic systems in their engines, also to control the actuation of landing gear, flaps, rudders, and brakes. This is thanks to a hydraulic system’s ability to withstand heavy loads and offers a smooth operation.

Whereas hydraulic systems are used for loading or unloading missiles to the launcher guide arm from the magazine stowage area, positioning missiles, or controlling missile flight attitude, pneumatic systems deploy solar panels and other vital components. Together, both systems offer safety, accuracy, and controllability in aircraft.

Advantages Of Both Halves of The Fluid Power System

Hydraulic systems are often preferred and used for moving heavy loads, mostly because they yield a greater force than mechanical, electrical, or pneumatic systems. More importantly, they are easy to control and act as a source of accurate or near-accurate energy supplies.

For many companies, some advantages of hydraulic systems include the following:

- High Power-To-Weight Ratio: As previously stated, hydraulic systems can generate an impressive high force that is almost intimidating compared to smaller sizes.

- Precise Control: Hydraulic systems allow for smooth, precise control of motion, making them ideal for applications that require accurate positioning and movement.

- Self-lubrication: Unlike several heavy pieces of equipment that need to be lubricated often, the hydraulic fluid used in hydraulic systems serves as a natural lubricant for all internal components. This minimizes the occurrence of friction or wear and tear in the system, both of which are problems that plague heavy equipment. However, hydraulic systems do require constant and regular maintenance to ensure the absence of fluid leaks.

- High Efficiency: With minimal energy loss through heat and friction, hydraulic systems are undoubtedly one of the most efficient power systems there are today.

While pneumatic systems may differ slightly from their hydraulic counterparts, they also offer unique advantages suitable for industrial uses in harsh military and aerospace environments. Some of these advantages are:

- Safety: Pneumatic systems use compressed, non-flammable gas. This makes it suitable for use in hazardous environments and danger zones, such as in flammable environments typical to the military and aerospace.

- Clean Technology: Pneumatic systems use air and not fluids, which makes them free from harmful chemicals and the possibility of contamination. This makes it a much cleaner technology that can be employed in applications that require a sterile environment.

- Affordability: Pneumatic technologies are more affordable and cost-effective than hydraulic systems.

- Simplicity: Pneumatic systems use fewer complex systems and fewer components than most technological situations.

- High Speed: Pneumatics can easily operate at high speed, which makes them a great option for operations that require a quick response (operations such as this one is typical in aerospace and defence tasks).

Future Trends and Challenges in Fluid Power Technology

Fluid power technology undoubtedly offers numerous advantages in numerous industries, including the forementioned aerospace and military industries. Its precision, strength, and efficiency make it one of the most effective energy systems today.

While fluid power has great potential in the power industry, it’s important to consider and address the various limitations that could affect its performance. By proactively identifying and managing these challenges, several companies in the power industry are working towards maximizing the benefits of fluid power technology and harnessing its full potential to drive innovation and progress. These limitations create an opportunity for future trends that will shape how fluid power systems evolve and adapt in the coming years.

Some of these trends and how companies are challenging them include:

1. Increasing Energy Efficiency

Fluid power systems are praised for their efficiency in creating energy. However, even state-of-the-art fluid power systems remain widely inefficient years after technological advancement. A recent study published by the United States Department of Energy estimated their average energy efficiency at only 21%. These inefficiencies are due to various factors, including pressure/flow losses and poor system designs.

Soon, fluid power systems will require innovative solutions that will minimize inefficiencies. Key industry players have already begun developing technologies needed to increase energy efficiency. This innovation will make these systems better, safer, and more cost-effective.

2. Developing Smart Components and Even Smarter Systems

The increased adoption of smart technology has spurned conversations about creating smart fluid power systems. By integrating the Internet of Things (IoT) and Industry 4.0 concepts in fluid power technology, industries aim to optimize performance, minimize maintenance, and make fluid power systems even more efficient.

With the application of sensors, data analytics, and machine learning, smart fluid power is only a few steps away. This will make it easier for fluid power manufacturers to add more intelligence and product differentiation to their fluid power systems.

3. Integration with Advanced Systems And Electronics

Right now, fluid power systems are barely toeing the line of integration with advanced systems and electronics. As aerospace and military operations became more complex over the years, this need has become more apparent as the years go by. However, companies such as Lynch Fluid Controls are taking on the challenge and spearheading the growth of digital fluid power systems through the invention of electro-hydraulic and electro-pneumatic fluid systems.

Electrohydraulic and electro-pneumatic are powerful alternatives that offer fluid power systems more flexibility and precision than they already have. This will bolster the application of fluid power in aerospace and military operations, making these operations more advanced.

4. The Need for Compact Designs

Fluid power systems are becoming increasingly smaller as compactness becomes a trend and need in major industries, especially aerospace and military. Industry-wide trends point towards miniaturization as many industries now seek to reduce large and bulky fluid power systems to smaller lightweight options. Today, industries are creating small fluid power systems that are compact and deliver high performance regardless of changes in size and weight.

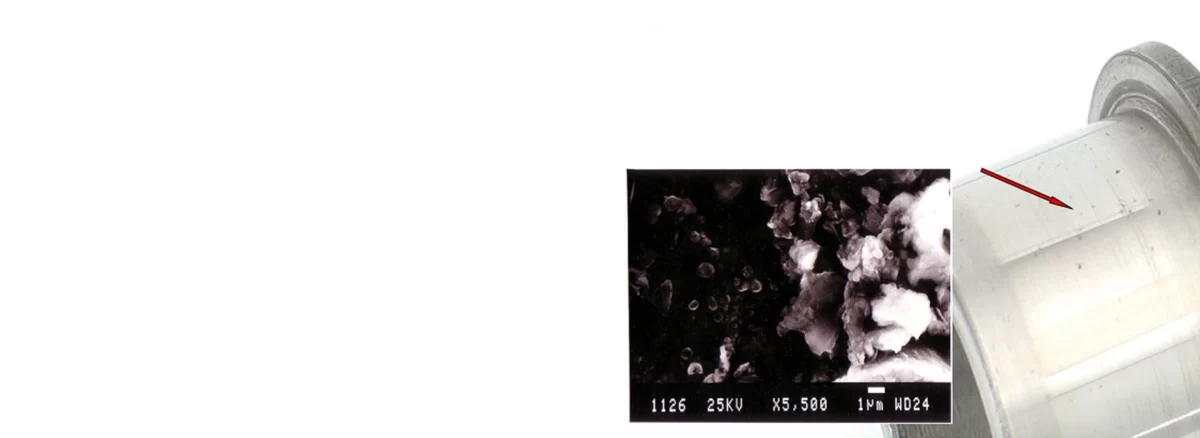

5. Addressing New Materials and Manufacturing Techniques

As new materials and manufacturing techniques are being discovered, so is the need to manufacture durable fluid power systems from these discoveries. The advent of these new materials will enable the creation of new components and overall durable fluid power systems that will be more precise and accurate than they already are. This, along with other trends, will most probably mark a more efficient and effective application of fluid power in challenging military and aerospace operations.

Real-World Military and Aerospace Applications & Technical Solutions

1. Advanced Flight Control Systems

Aircraft use fluid power systems- both pneumatics’ and hydraulics- to activate and manage equipment such as ailerons, flaps, thrust reversers, and flight controls. This function is necessary for precise control over aircraft movement, ensuring safe and efficient flight operations.

Technical Solution: The combination of electric and fluid power in Electro-hydraulic actuators (EHAs) and electro-pneumatic actuators (EPAs) is becoming more popular in advanced flight control systems. This is mostly because they combine the precision of fluid power with the control of electronic systems. Together, EHAs and EPAs improved efficiency, reduced weight, and simplified system architecture, features traditional fluid power systems lack.

2. High-performance Landing Gear Systems

Hydraulic systems independently play crucial roles in an aircraft’s ability to land. They enable the extension and retraction of gear assemblies and work to provide shock absorption while landing. Together, the landing gear works to reduce the risks of accidents.

Technical Solution: The energy efficiency of landing gear systems has been increased through the development of regenerative circuits in hydraulic systems.

These devices recapture heat energy that would otherwise be lost during gear retraction and use it to power the extension process instead. As a result, the system becomes more efficient overall and uses less energy.

3. Precision Weapons Solution

In defence, fluid power is used to operate systems that require high precision and force, such as missile launchers, artillery, and tank turrets. Fluid power systems need to be compact enough to fit into these structures and can also pack enough punch to deliver efficient force.

Technical Solution: The precision, speed, and dependability of weapon systems are being improved by developing sophisticated hydraulic and pneumatic systems. They consist of closed-loop control systems, which continuously modify system parameters based on data from sensors and actuators to ensure optimal performance under various circumstances.

4. Maintenance and Ground Support Equipment

Specialized maintenance and ground support tools, including hydraulic lifts, jacks, and testing equipment, are frequently needed for military and aerospace activities. These vital support instruments can only operate smoothly and effectively thanks to fluid power systems. Without an efficient fluid power system, many of these operations are at risk of failure.

Technical Solution: The efficiency and efficacy of ground support and maintenance machinery can be improved by introducing IoT-enabled fluid power components and systems. With these components, it will be easy to foresee maintenance needs, minimize downtime, and enhance performance by gathering and evaluating data from sensors integrated into these systems.

Innovative Fluid Power Solutions by Lynch Fluid Controls

When it comes to designing and creating advanced hydraulic systems, Lynch Fluid Controls is a key player.

The company is armed with ISO 9001:2015 and AS9100D certifications and years of providing service in the fluid power industry, qualities that have made them a trusted partner for military and aerospace fluid power applications.

Some areas where Lynch Fluid Controls is contributing to the fluid power needs in industries includes:

1. Custom-created Solutions

Lynch Fluid Controls has gathered extensive knowledge about the unique requirements of aerospace and military applications. As such, their teams offer custom-designed solutions tailored to meet specific aircraft and defense needs. They possess the expertise and experience necessary to create cutting-edge fluid power systems that meet or beat performance benchmarks set by the industry.

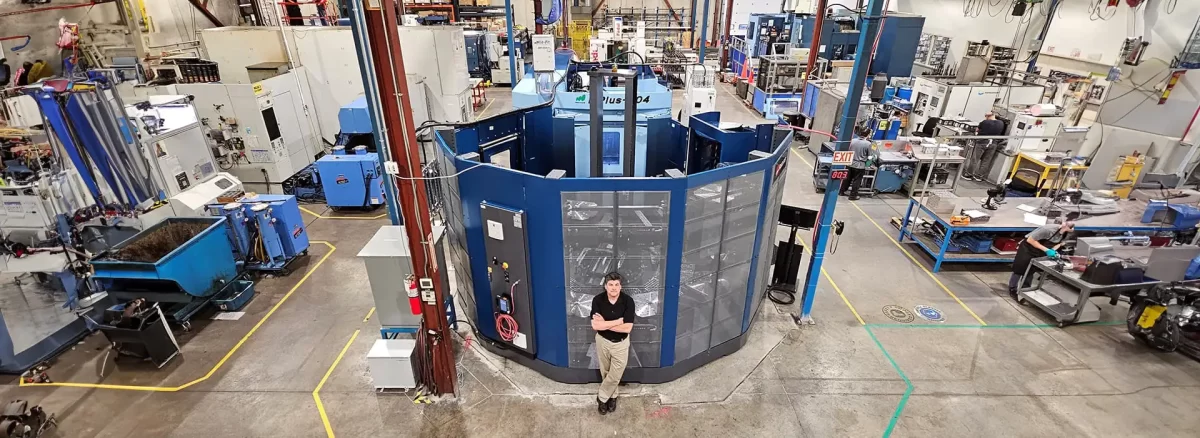

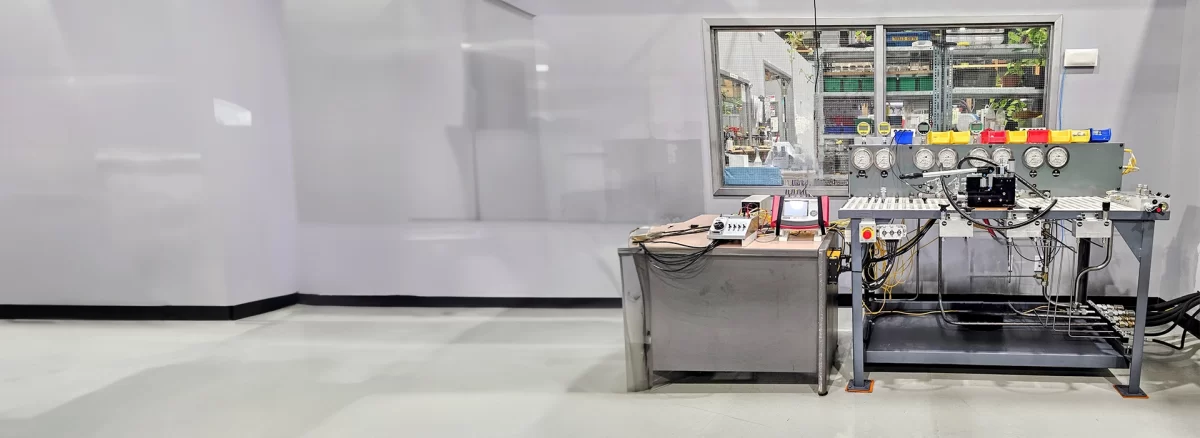

2. Cutting-edge Manufacturing Capabilities

Lynch Fluid Controls utilizes ultra-modern manufacturing facilities and industry-standard processes to ensure the manufacturing of high-quality fluid power components and systems. Using cutting-edge machining capabilities and quality assurance procedures reduces flaws and ensures that all fluid power systems manufactured exceed the specifications needed for aerospace and military applications.

3. Adaptation to cutting-edge control systems

Lynch Fluid Controls takes fluid power technology a step further than most by merging fluid power systems with advanced control systems and electronics. By doing so, they create systems with more precise control and monitoring of fluid power components. This improves diagnostics and enhances maintenance, thereby ensuring the fluid power system offers the optimal performance and reliability needed to be applied in the military and aerospace industry.

4. Embracing Smart Technologies

Lynch Fluid Controls is committed to remaining at the forefront of technological improvements and advancement. This is exactly why they are embracing the benefits of modern smart technologies such as the Internet of Things (IoT) and Industry 4.0 in their fluid power solutions. By doing so, they improve fluid power system designs to enhance fluid power reliability, efficiency, and efficacy in aerospace and military industries.

Conclusion: Fluid Power for The Future Of Aerospace And Military

Overall, it is impossible to overrate the importance of fluid power in aerospace and the military. Fluid power technology is integral to the success of operations in both industries, offering precision, force, safety, and reliability in critical tasks using equally critical systems.

Admittedly, the fluid power industry is not entirely rid of limitations that challenge its potential, especially in aerospace and military operations. However, by understanding these challenges and offering tailored solutions that address these needs, the industry can tackle these limitations and use them as leverage to make fluid power technology a better version of what it already is.

Lynch Fluid Controls, already a key player, is poised to contribute significantly to the future of fluid power technology through evolving manufacturing, efficiency and technologies needed for complex systems and equipment. Using its extensive experience, and advanced manufacturing capabilities, the company seeks to continue to provide innovative solutions to meet the fluid power industry’s rapidly changing needs.

Fluid power will continue to be essential in developing aerospace and military systems due to the constantly changing technical landscape, ensuring that mission-critical activities are safe, effective, and dependable.

Further References

The Future of Fluid Power: 6 Challenges Facing Hydraulic Engineers – Moog, Dave Geiger

Electro-Hydrostatic Actuation: An Attractive Energy-Efficient Option for Machine Builders – Achim Helbig, Ph.D.